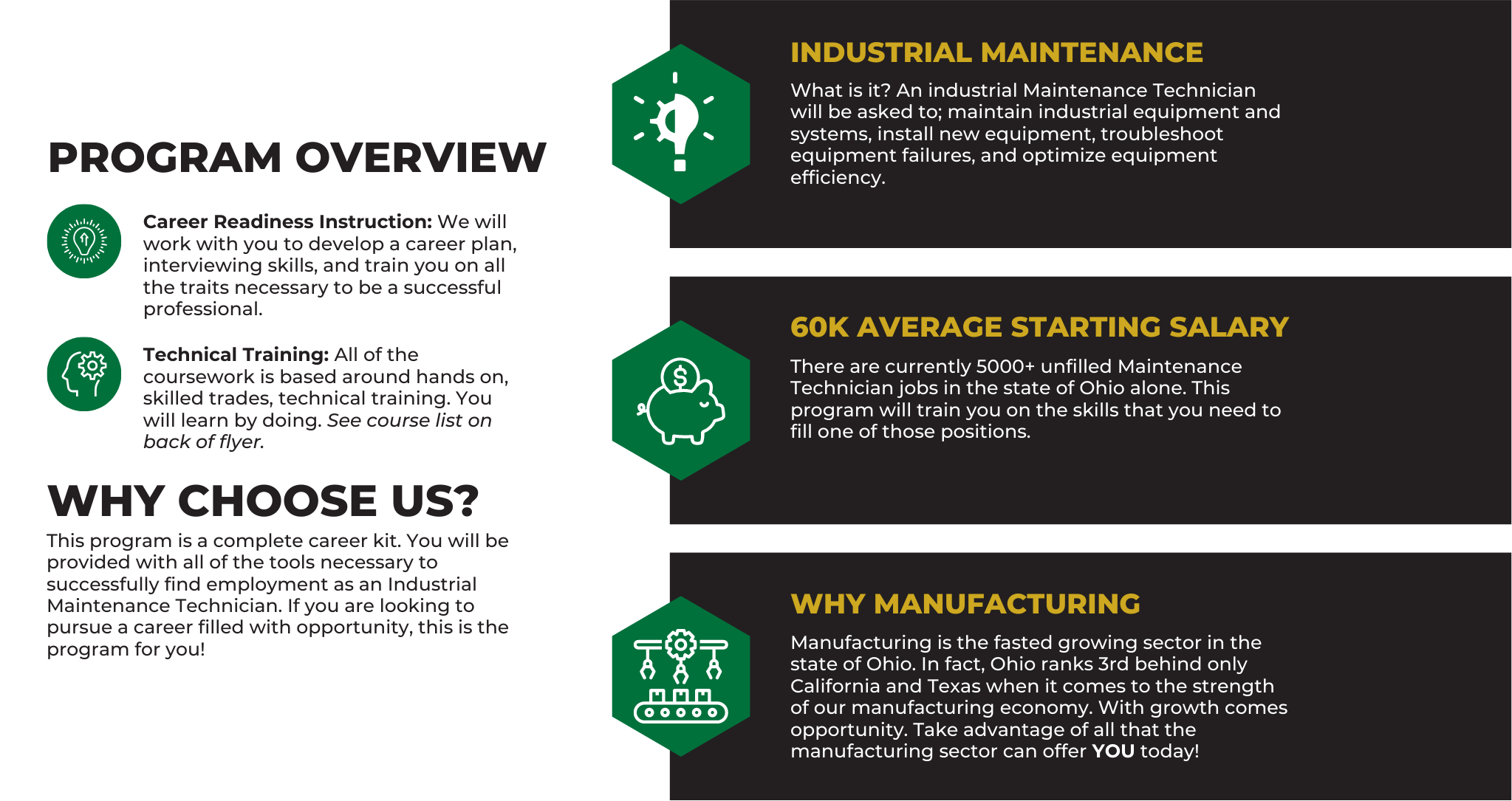

WLD 110 : Introduction to Applied Welding Techniques

This is an introductory course where students will develop knowledge and skills thru theory and lab practices. Basic welding processes will be covered including; SMAW, GMAW, OAW, PAC, and OAC. Safety will be emphasized throughout the class and will be in accordance to industry standards for manufacturing.

IND 120 : Industrial Electricity I

This is an introductory electricity course for skilled trade’s personnel. The course is a study of DC and AC electricity principles, with a practical approach to applications in an industrial environment. The learner will obtain a knowledgeable understanding of the key symbols and abbreviations associated with the electrical trade, acquire a comprehensive understanding of basic electrical terminology, apply Ohm’s Law to a number of relevant electrical applications, and synthesize a number of components into a working system involving series, parallel, and series parallel circuits.

IND 132 : Bench Work

This is the first basic machine shop course in which students learn the use of hand tools. Students are required to select appropriate tools and identify machining processes with emphasis on safety, tooling, precision, and accuracy. Topics include: materials, mechanical fasteners, measurement, tolerance, fit, layout, hand tools power tools, drilling, grinding, sharpening, hardening, deburring, filing, polishing, layout work on the bench, use of hand taps, and cutting threads with a die.

IND 121 : Industrial Electricity II

This course is an advanced study of industrial electricity that provides a comprehensive coverage of the types of control devices that are used in contemporary industrial electrical systems. The focus of this course is to provide the solid foundation of electrical knowledge and skill that is required in an advanced manufacturing environment. The course continues from IND 120 with electrical and motor theory, building on circuit fundamentals. Theory is reinforced with practical hands-on labs, giving the learner control systems design experience. These topics will be learned through text, presentations, various exercises, and hands-on labs.

IND 131 : Industrial Pipefitting

A study of the specifications, application, installation, and maintenance of various kinds of pipe, fittings, valves, pumps, and hand tools. The analysis of job requirements in terms of materials. time utilization and sequence of operation is discussed.

IND 134 : Industrial Fluid Power I

Fluid power is an efficient way to move energy without mechanical belts, chains, or levers. The physics of fluids, components, and troubleshooting and design applications for hydraulic and pneumatic systems are covered in the course.

PLC 200 : Programmable Controller I

The course is a study of the installation, programming, and troubleshooting of programmable controlled systems currently used in an industrial environment. The focus will be on installation, programming, engineering, and maintenance tasks performed with PLC systems. The primary PLC used for this class will be the Allen Bradley SLC-500, using RSLogix 500 and RSLinx software. The topics presented will be learned through text, presentations, various exercises, and hands on labs.

IIND 223 : Motors and Motor Controls

This course is an advanced study and laboratory for learners who have an understanding of electrical circuits and controls, and desire practical hands-on experience of various motor and control devices. Coursework involves hands-on laboratory experience utilizing 120 VAC, 208/240 VAC, as well as text study. Practical applications of the principles that are learned will be emphasized. Topics of study will include ladder diagrams and their control of alternating and direct current motors. Motor starter sizing, circuit/overload protection, and electrical motor branch wiring will also be introduced. The Variable Frequency Drive as a motor controller will also be discussed at length along with the application of programmable logic controllers in motor control circuits.

IND 232 : Machine Repair

This course covers the basic fundamentals of the methods and means of rebuilding an industrial production machine. Concepts such as alignment, bearing replacement, gear systems, chain drives, pulley drives, etc. will be discussed and preformed through extensive hands-on labs.

PLC 230 : Servo/Robotics Systems

Servo/Robotics Systems is an introductory course in industrial robotics with emphasis on the Fanuc R-J3 series robot. The course is intended for students who wish to gain insight into robot operations in order to setup, test, run, and refine application programs for production. Students successfully completing the course will be able to: power up and jog the robot, execute production operations, recover from common faults, create and modify material handling programs and macros, and utilize robot input and output signals. The course consists of lectures, demonstrations, and a series of laborator exercises using the Fanuc CERT training modules.

Find Out More!

Participants must be at least 18 years old and eligible to work in the U.S.

Connect with Us